SignRacer

Industrial LED UV large-format printers with linear motor technology

Combining precision with speed, nothing comes close to the quality of the SignRacer range of UV printers. Print in vivid colour with the extended-gamut inkset which includes bright Yellow and Magenta as well as Orange and Violet for an unrivalled gamut. White and Varnish inks onboard for creative effects as well as jettable Primer for the most difficult substrates.

The latest Ricoh Gen6 heads as standard in up to three rows for extreme speed and multi-layer printing.

Print on objects up to 500mm high and in unlimited layers for 3D effects.

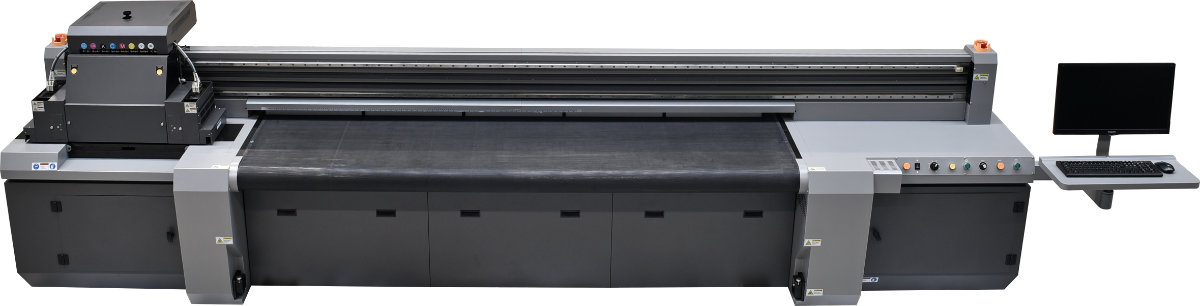

Flatbed

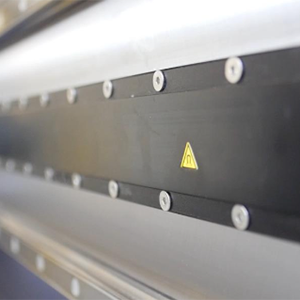

When precision is key, then a flatbed is the perfect solution. The vacuum bed has alignment rulers on each edge and retractable alignment pins for precisely locating your media on the bed. These machines are able to print on rigid or flexible medias up to a thickness of 500mm. The vacuum pumps can also be reversed to blow, so that heavy medias can be floated into position. Because of the high precision, 3D effects such as Braille can be created with an unlimited number of layers on top of each other.

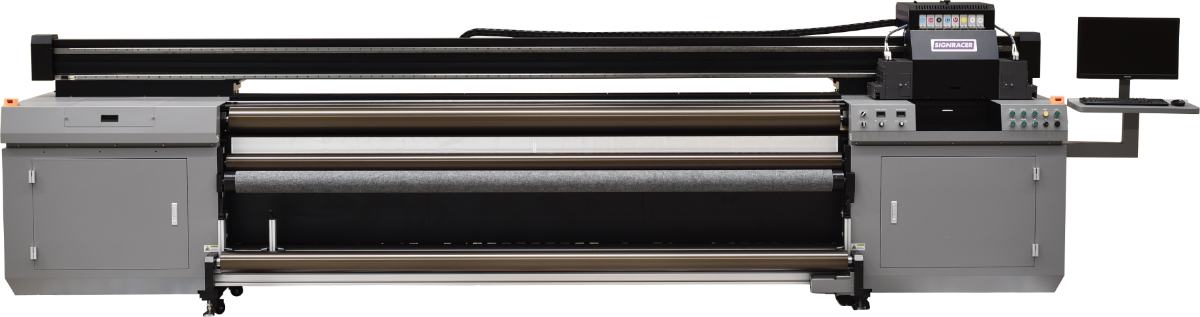

Hybrid

For ultimate flexibility, a Hybrid machine combines the best of both worlds. Print on rigid and flexible materials with precision. Ideal for high-volume production needs. The media is driven under the print area by the conveyor vacuum belt, allowing roll-to-roll printing as well as rigid materials. The included extension tables allow rigid materials up to 100mm thick to be fed through the machine with ease.

Roll-to-roll

Large format LED UV roll to roll printers are digital printers capable of printing onto wide rolls of media. They use LED UV curing technology, which uses ultraviolet light to quickly dry and cure ink, allowing for fast production. Super-wide, up to 3.2m. Super-speed, up to 156 square metres per hour. These printers are used for a variety of applications, including banner printing, vehicle wraps, and large-format signage.

High Bridge

Developed with industrial customers in mind, the SignRacer 2512 HB is a unique printing system with a carriage height adjustment system utilising a robust industrial high-bridge design that can print up to heights of 50 cm. Not only that, but it also boasts high speeds and quality, along with high adhesion and flexible UV inks to enable printing on a range of challenging material surfaces such as plastic components, metal parts and leather products.

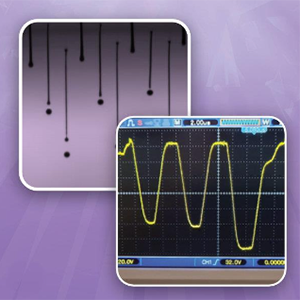

The automated height adjustment system along with the linear motor and encoder enables precise three dimensional printing with high production speeds.

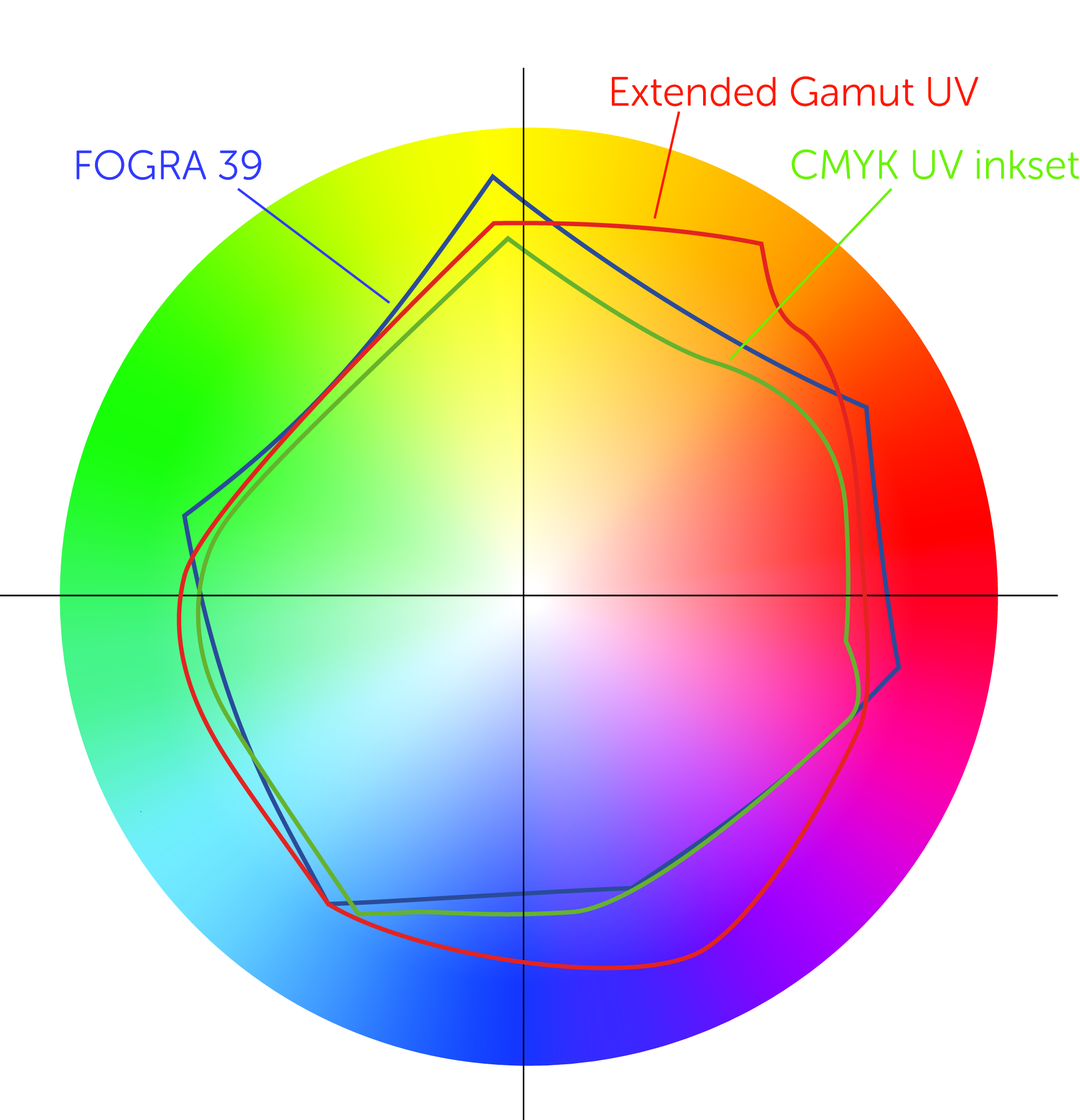

Extended-Gamut Inkset

UV printing dries the ink by curing with UV lamps. Because of this it can print on practically anything. The physical problem of achieving a good colour gamut with UV printing is that the ink droplet never gets “into” the printed surface. The droplet is cured instantly as it sits on top of the surface. We can’t add more ink to the surface without increasing the thickness of the layer which then causes other problems. Also, the droplets do not dry flat against the media giving a matt effect by dispersing light – an enemy of colour saturation.

Chemistry also works against UV technology because the chemicals needed to control properties like UV curing, adhesion, viscosity etc will not all be colourless. It’s particularly problematic with Yellow – most UV Yellow inks tend to have a muddy greenish hue. It’s against all this that we’ve been working to improve what can be achievable with the range of SignRacer UV printers.

The first step has been the addition of Orange and Violet inks. You can see in the gamut map image the difference in those colours compared to the previous inkset. Importantly, it’s pushed the boundary in those areas past FOGRA 39.

The second step has been a reformulation of the Yellow and Magenta inks. New chemistry has enabled a brighter, less muddy colour which has improved not only their primary colour but also secondaries using those inks such as green and blue.

The total increase in gamut volume from the previous inkset is 23%.

Key Features

Special Applications

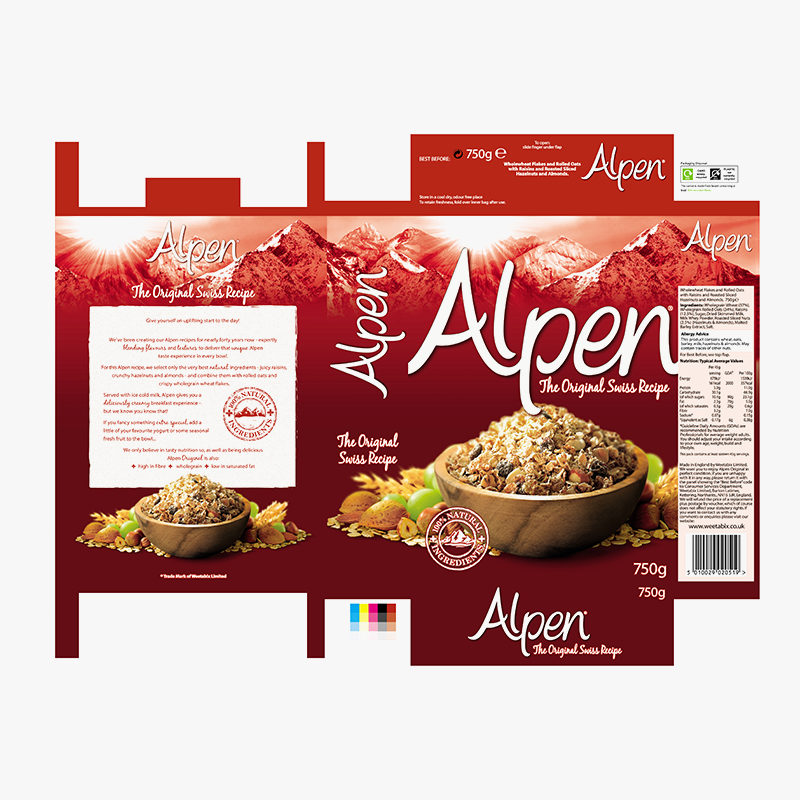

Packaging

SignRacer’s variable dot technology with the Ricoh Gen. 6 print head makes us the ideal partner for the packaging industry. The SignRacer HD can print mock-ups with the smallest letters and special effects like varnish, ensuring high-quality packaging visualisation solutions on actual packaging materials including shrink-wraps.

Car Interior Customisation

In today’s automotive industry, custom car interiors have evolved beyond simple aesthetics—they are now a statement of individuality and luxury. SignRacer empowers car interior customisation companies with high-performance UV printers that allow for the creation of intricate, durable, and visually stunning designs. Whether printing on rigid surfaces like dashboards or flexible materials such as leather, SignRacer’s UV printing technology ensures top-tier quality and lasting results.

Watchfaces

In the world of watchmaking, every detail counts. Therefore, watch dial digital printing offers unparalleled precision and customisation, allowing manufacturers to create unique and high-quality designs that captivate customers. Moreover, by leveraging advanced technologies, SignRacer ensures that your watch faces not only meet but exceed industry standards.

Printing on Leather

UV printing on leather has become an essential aspect of various industries, including fashion, interior design, and luxury goods. SignRacer offers cutting-edge solutions for leather printing using UV technology through their flatbed and hybrid printers. With the integration of PremiumFlex+ inks, their printers ensure high-quality, durable, and flexible prints on both genuine and faux leather

Braille UV Printing

SignRacer provides innovative solutions to meet the growing demand for high-precision Braille printing across Europe. The Braille UV printers use advanced LED UV technology to create durable, EAA-compliant tactile signage that is both visually appealing and tactually accurate. Whether you’re producing Braille signage for public spaces, educational institutions, or commercial environments, SignRacer Braille UV printers ensure the quality and efficiency you need for all your accessibility printing needs.

Custom Printing On Hard Cases

SignRacer provides comprehensive state-of-the-art solutions for custom printing on musical instrument cases and transportation suitcases. The advanced flatbed printing machines, combined with specialised high-quality inks, enable the creation of personalised and durable designs tailored to both individual and commercial needs.

Glass Printing

With the high adhesion inks from SignRacer it is possible to print on glass without any primer. The high adhesion character of the ink is also usable for safety glass. Many creative effects are possible with the use of White and Varnish inks. Reverse printing with a White backing layer as well as sandwich printing Colour-White-Colour layers for day and night visibility are simple through the advanced control software. Frosting effects can be achieved with the Varnish ink set to Matt finish in various patterns.