The advantages of UV inkjet technology have seen it take-off worldwide in recent years. Despite all the advantages it’s always had it’s one Achilles heel – namely “Gamut” or rather, lack of it.

Compared to other inkjet technologies, UV has both physics and chemistry against it in creating the depth and range of colours available in Aqueous and Solvent methods.

Aqueous tends to have the largest colour gamut out there. Using water as the carrier for the pigment particles, it needs media that is specially coated with a receptive layer. This acts like a sponge, absorbing the pigment as the water evaporates. This depth of coating allows for more pigment to be held than if it just sat on top of the media. Therefore more depth of colour, larger colour gamut.

Solvent printers use the solvent as the pigment carrier and it dries by chemically bonding to the media rather than needing a receptive layer. As with Aqueous technology we get a depth of pigment deposited into the surface giving a good colour gamut.

UV printing dries the ink by curing with UV lamps. Because of this it can print on practically anything. The physical problem of achieving a good colour gamut with UV printing is that the ink droplet never gets “into” the printed surface. The droplet is cured instantly as it sits on top of the surface. We can’t add more ink to the surface without increasing the thickness of the layer which then causes other problems. Also, the droplets don’t dry flat against the media giving a matt effect by dispersing light – another enemy of colour saturation.

Chemistry also works against UV technology because the chemicals needed to control properties like UV curing, adhesion, viscosity etc will not all be colourless. It’s particularly problematic with Yellow – most UV Yellow inks tend to have a muddy greenish hue.

It’s against all this that we’ve been working to improve what can be achievable with our range of SignRacer UV printers.

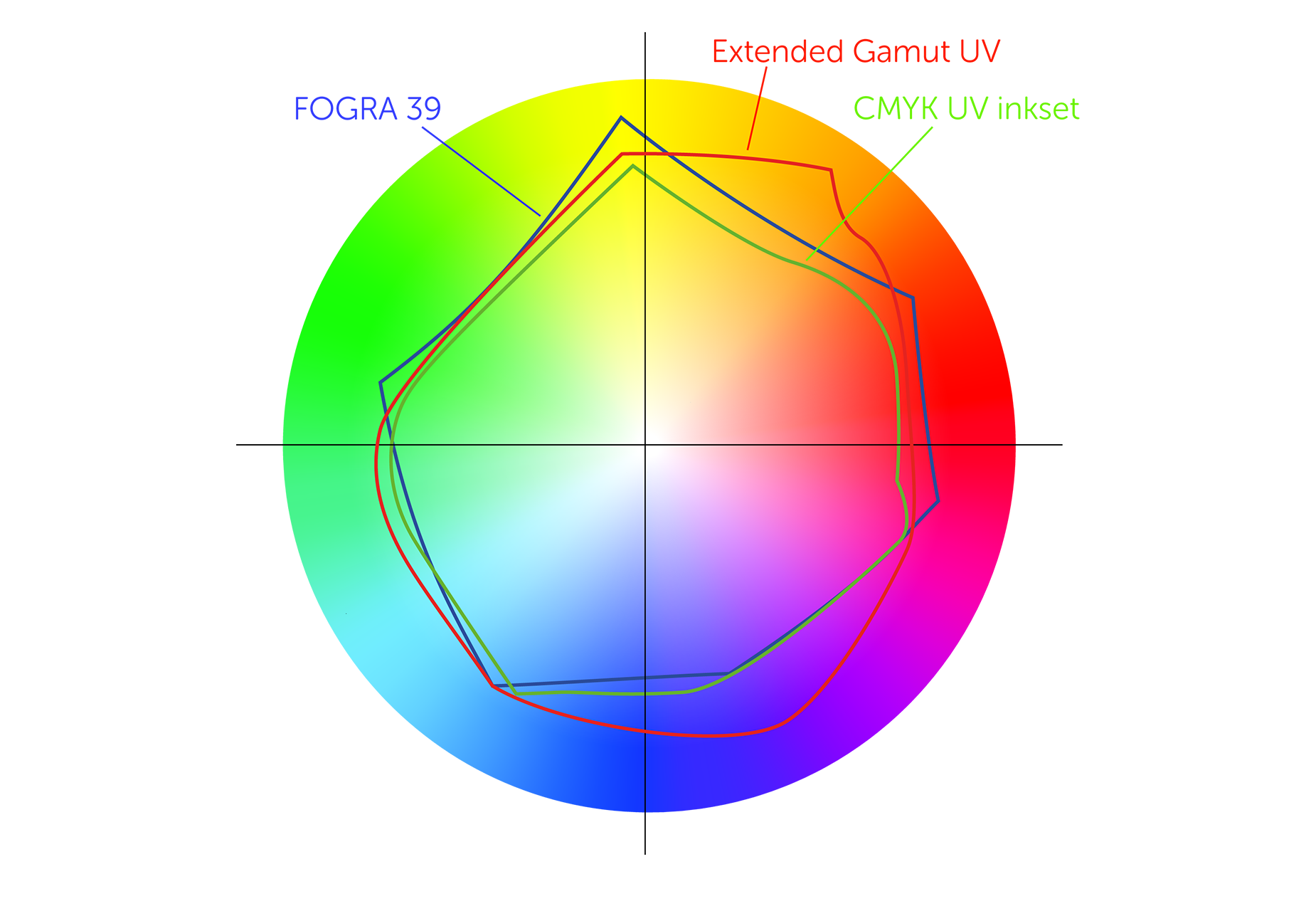

The first step has been the addition of Orange and Violet inks. You can see in the gamut map above the difference in those colours compared to the previous inkset. Importantly, it’s pushed the boundary in those areas past FOGRA 39.

The second step has been a reformulation of the Yellow and Magenta inks. New chemistry has enabled a brighter, less muddy colour which has improved not only their primary colour but also secondaries using those inks such as green and blue.

The total increase in gamut volume from the previous inkset is 23%.

The inkset is called SignRacer Industrial and is compatible with all Ricoh and Kyocera printheads used in the SignRacer range.