Flex Pack

The ultimate proofing solution for packaging

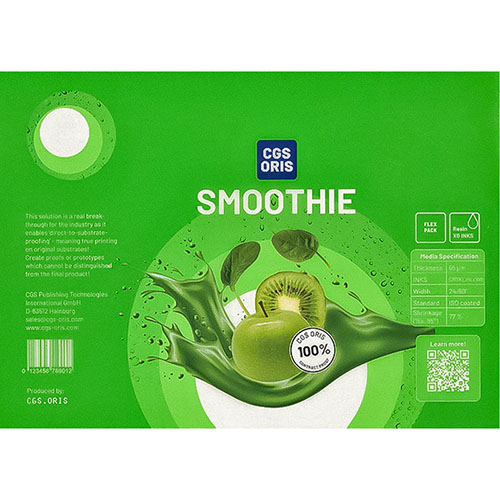

Real substrate proofing enables proofs to be printed directly on the target production substrate, resulting in a proof that is indistinguishable from the final production run. Exclusive newly-developed inks include CMYK/OGB/White and deliver exceptional quality and colour gamut. Print on any packaging substrate with 100% gamut and 100% confidence.

Proof on final substrates

Developed in partnership with Mutoh, real substrate proofing enables production of proofs, prototypes, mock-ups and samples on the final target production substrate.

Accurate Look And Feel

The look and feel and all other physical properties of the substrate are retained, making it possible to create a packaging proof or prototype which cannot be distinguished from the final product. Unlike traditional systems, our proofing system delivers samples and mock-ups that have the exact same look and feel as your finished product.

Covers Pantone Library

The brand new ink set, specifically designed for use with FLEX PACK software, includes CMYK and orange, green and blue and covers nearly 100% of the Pantone Library. It delivers exceptional color quality and gamut.

Improve communication with brand owners thanks to a true representation that looks & feels exactly like their final product. This breakthrough proofing solution is set to transform the way prepress houses and packaging converters produce packaging proofs for their brand owner customers.

Improve your communication with brand owners during the design process and the press approval process.

Gain important competitive advantages as you can provide something very few others can offer.

Save a great amount of time and money thanks to a shortened approval cycle and no press proof costs.

Revolutionising packaging printing

Join Heiner Müller, Sales Director at CGS ORIS, as he introduces real substrate proofing, a groundbreaking solution set to transform the way packaging proofs, samples, and mock-ups are created. In this video, we explore this revolutionary technology.

The power of shrink sleeve printing

Let us explore the intricacies of printing on shrink sleeves, showcasing how our solution ensures colour accuracy and precise distortion control, even with high shrink factors of up to 75%. Real substrate proofing boasts an extensive colour gamut, faithfully reproducing spot colours and overprints using spectral colour definitions.

Mastering metal printing

Join us as we explore the complexities of metal printing and unveil the game-changing capabilities of real substrate proofing. In this video, we dive deep into the challenges of metal printing and demonstrate how our cutting-edge technology offers unmatched solutions.

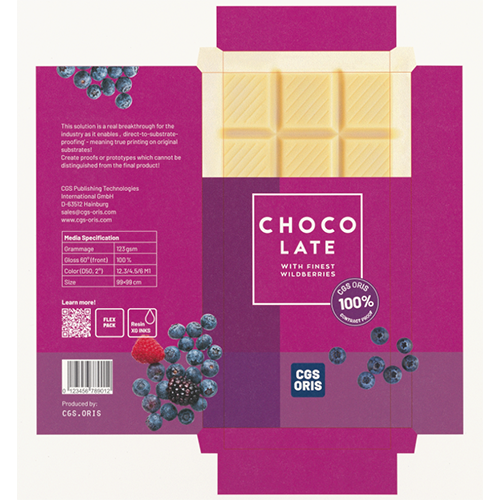

Perfecting carton printing

Let’s explore the intricate world of carton printing with our real substrate poofing system. Learn more about the diverse challenges of carton printing, from sustainable packaging trends to intricate finishing effects.

The Flex Pack system from CGS ORIS, is a truly revolutionary approach to creating proofs, samples and mock-ups for packaging using the final target substrate, an approach previously not possible. Traditional proofing involves the use of expensive, specialised substrates that lack the true final appearance of the package.

The Flex Pack solution developed jointly with Mutoh, includes:

- Mutoh VJ-628MP or VJ-1628MH printer

- A compact footprint that fits in even the most space-constrained operations

- Best-in-class print quality

- Exclusive water-based resin inks in CMYK plus orange, green, blue and white with good adhesion on almost any surface

- A huge colour gamut covering 97% of Pantone colors

- Odourless

- High flexibility

Our multi-resin inks feature excellent adhesion and unique stretching and shrinking properties, enabling printing directly to shrink sleeves and other thin films as well as corrugated boards, metal, uncoated label stock, folding carton board and more.

Printing directly to shrink sleeves offers a unique solution whereby brand owners can shrink the film onto the target packaging to validate accurate distortion of the artwork in advance of production. This is not possible with traditional proofing and prototyping solutions.

Packaging proofs made perfect!